Reator de aquecimento por indução elétrica de alta pressão

O Reator de Aquecimento por Indução Elétrica de Alta Pressão utiliza indução magnética para gerar calor internamente ao reator para processos químicos ou industriais, eliminando a necessidade de combustíveis fósseis e reduzindo a perda de calor. Pesquisadores estão desenvolvendo projetos sofisticados, como aqueles que incorporam susceptores de metamateriais, para aquecer todo o volume do reator de maneira uniforme e eficiente, criando uma alternativa mais limpa, precisa e sustentável aos métodos tradicionais de aquecimento.

- HXCHEM

- China

- 100 dias após o pagamento

- 20 conjuntos/mês

Detalhes

High Pressure Electric Induction Heating Reactor

High efficiency heating method for Chemical reactors

Introduction

An electromagnetic heating reactor uses induction heating to generate heat directly within a reactor's material through electromagnetic fields, replacing traditional combustion-based methods for chemical processes.Traditional reactor commonly uses electric heating elements, steam produced by boiler or thermal oil as its heating method. There are several issues such as environmental pollution, low energy efficiency and hidden safety hazards, which are long-term problems that affect the survival and growth of companies. Utilizing manufacturing equipment with alternative and clean energy sources has become urgent concern for the entire industry.

Electricmagnetic heating also called induction heating, is an ideal alternative to increase production efficiency and lower energy consumption. Using induction heating in chemical reactor, especially stainless steel reactor, the liquid and solid materials inside the reaction vessel can be efficiently and evenly heated, and can avoid material loss caused by uneven heating which often occurs in traditional heating system.

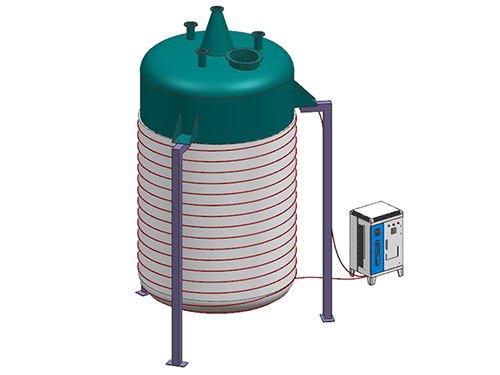

Reactor/ Kettle/ Vessel volume: 100L---20000L

Maximum temperautre: 450C-600C

Material:Carbon steel,Stainless steel, Clad steel.

1000L High pressure chemical reactor with induction heating device.

Benefits of Induction Heating

· Energy efficient

Induction heating is over 98% efficient at converting electricity to heat, providing energy savings of 30% and more.

· Safe and reliable

Coupled with intelligent control, the induction heating eliminates the need for open flame and heating mediums, ensuring a safer operation.

· Eco-friendly

With no need for open flame, induction heating does not produce dust, odor, noise and hazardous gases, compliant with the requirements of National Energy Conservation Policy.

· Digital control

Digital control system ensures accurate temperature control, offering an intelligent operation.

· Compact structure, easy maintenance

100L resin reactor with induction heating

What’s Induction Heating?

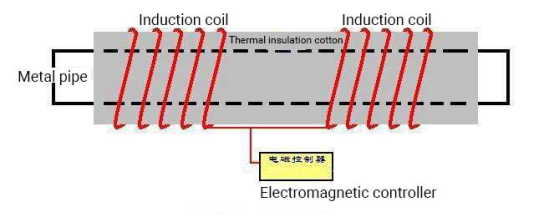

Electromagnetic induction heating, or electromagnetic heating (Electromagnetic Induction Heating abbreviation: IH) technology, is the principle of electromagnetic heating through the composition of the electronic circuit board to produce an alternating magnetic field, when an iron containing container is placed on it, the surface of the container is cut alternating magnetic force line and produces alternating current at the bottom of the container. Eddy current makes the carrier at high speed move irregularly at the bottom of the container, and the carriers collide with each other and produce heat. So that the effect of heating items. Because the iron container is self heating, the thermal conversion rate is particularly high, up to 95%, which is a direct heating method.

The Electromagnetic Induction Heating System Is Composed Of An Electromagnetic Heating Controller(induction heater) And An Electromagnetic Heating Coil.